1-8-2019

Flush mount electrical devices

Inventor: Marty Guthmiller

Original Assignee: Marty Guthmiller

Priority Date: 2018-12-6

Family US(1)

Info: Patent citations (?)

External Links:

Abstract

A system of parts that allows the mounting of electrical device either low voltage or line voltage to be mounted flush with the drywall when completed. This will allow full usage of the device but yet eliminate the need for a surface mount wall plate and make it virtually disappear when installed. It will end up flat with the wall when installed and can be painted the same color as the wall.

Claims

The system is comprised of several parts including but not limited to the following

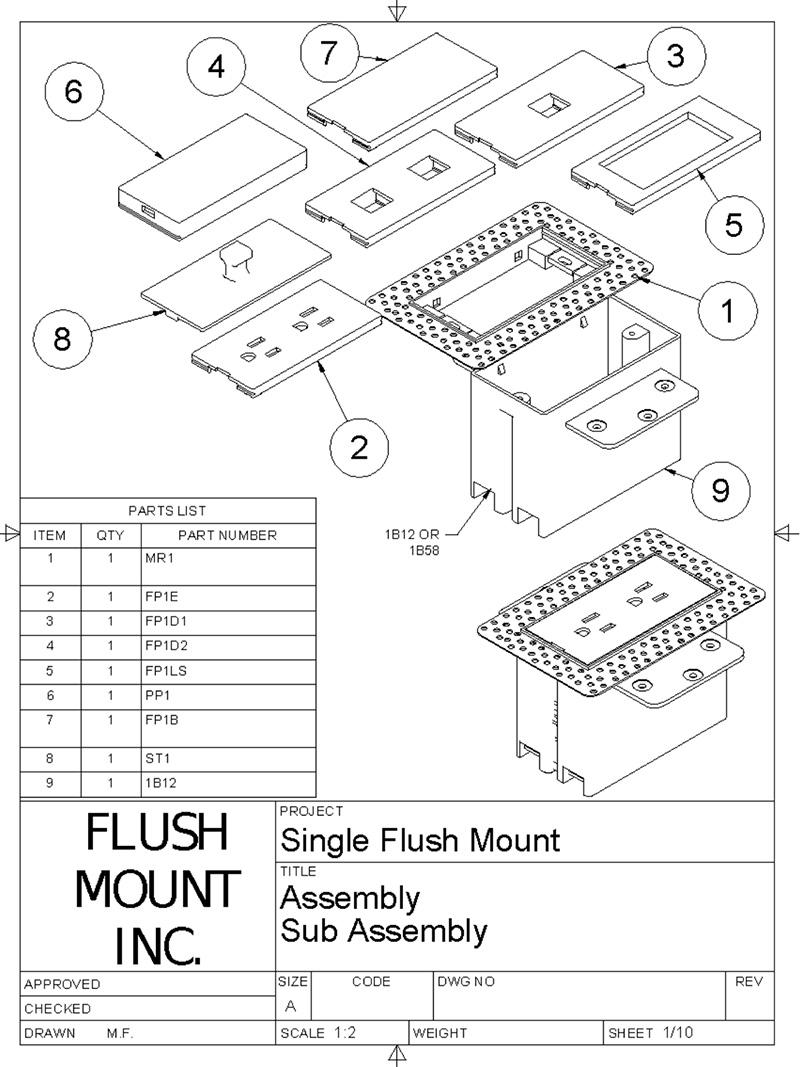

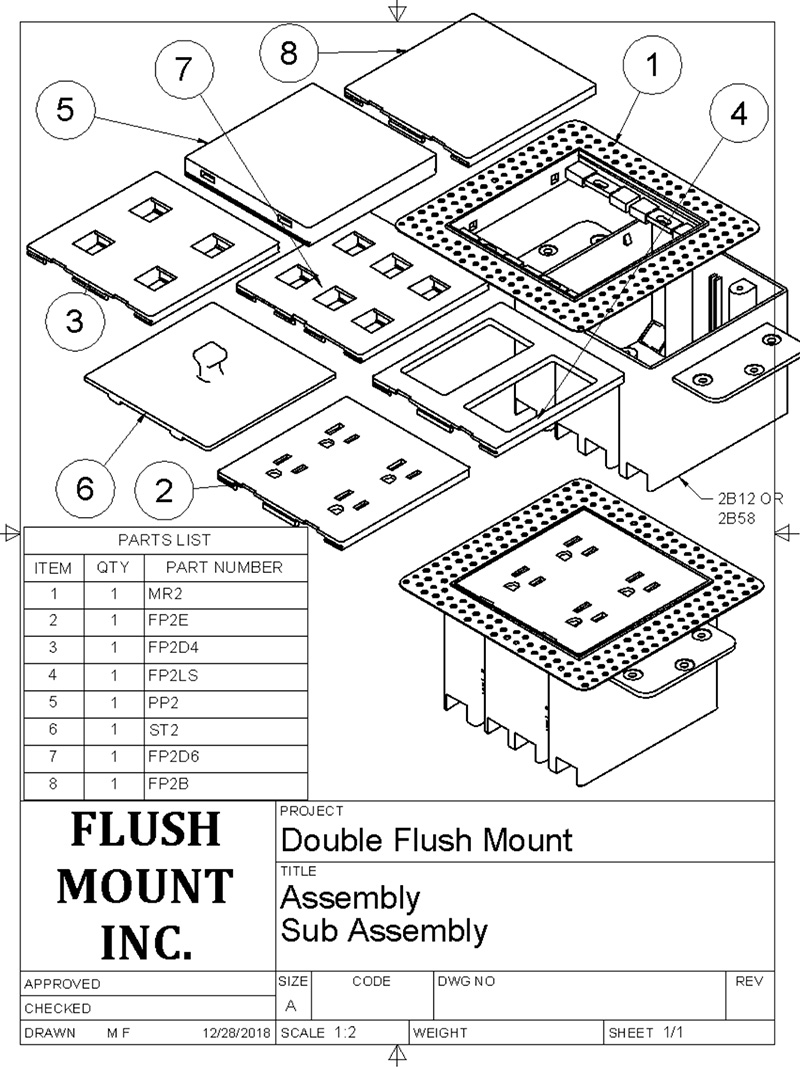

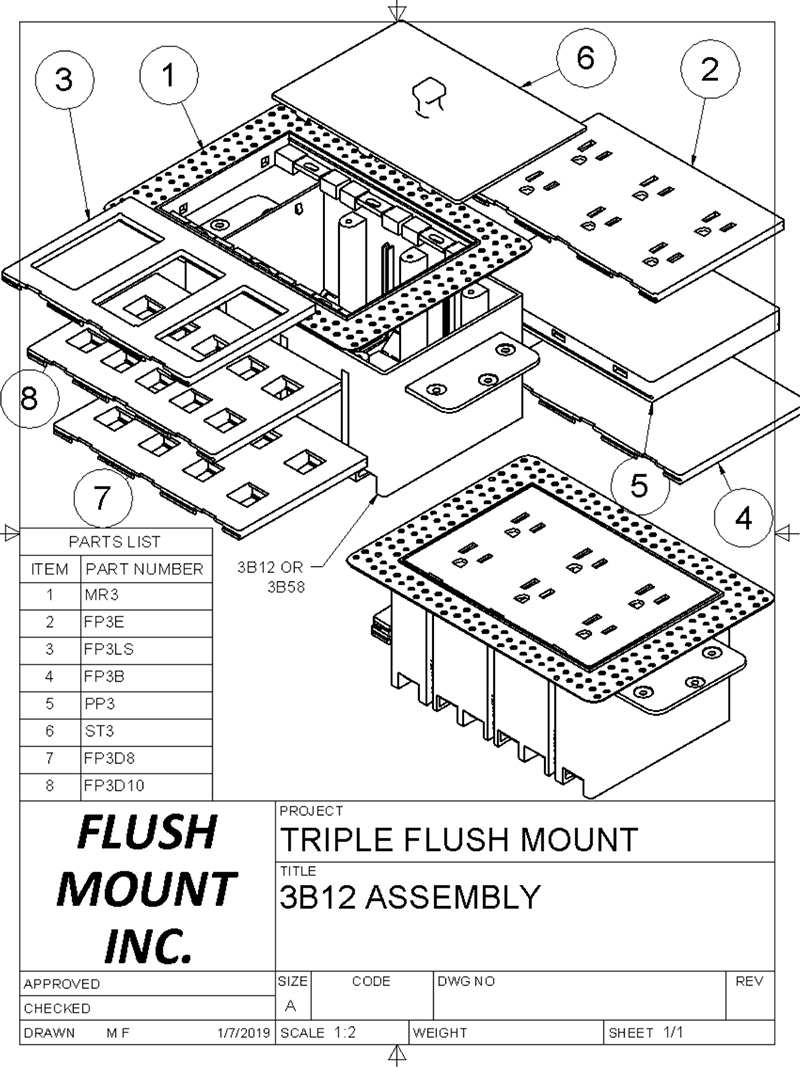

The back box. This is a box that is designed to be Nailed or screwed to the studs in a wall while the Building is being constructed. It has a closed back and has two ears on tabs on the front that will allow It to end up flush or flat with the drywall or other surface when installed.

The half back box. This like the back box but it is just the section of the box including the ears or tabs forward. This has no back and is designed to be used for low voltage when there is no electrical requirement the calls for a fully enclosed box.

The mud ring. This is a device that is rectangular in shape. And bigger than the box itself. It is designed to be inserted into the box after the drywall is installed. This will snap into the face of the box and hang over the edges of the drywall. It will have holes or slits in the face so that it will have crevices in it so the drywall mud or plaster can stick to it and the wall to help hold it in place and keep the drywall or plaster from cracking. The ring. Has a small lip or protrusion on the top and bottom of the hole, this is to lock in the face plate when it is installed. The ring also has a breakaway piece at the top and bottom of the opening. This is so that the single light switch or outlet can be installed with the same ring. If you are installing a light switch you will want to leave the tabs in place but if you are installing an electrical outlet you will want to remove them. There are also two small holes on each side of the inside of the ring. These are to mate with the tabs inside the box so they will lock together.

The Faceplate. This is designed to sit flush or flat with the drywall or plaster. It will snap into the mud ring. It will sit up against the shoulders that are inside the mud ring. The plate is designed to be installed by pushing it into the mud ring and the top and bottom of the two units will snap together. The plate has several versions. You can also do multiple different plates in the multi gang mud rings so you can configure the wall boxes in whatever way you need to complete your project. There is a small notch on the bottom of the plate that will allow you to stick a screwdriver or a device into it and pop the plate off for service.

Electrical outlet plate. This is designed to be installed in the front of a standard decora electrical outlet. This can be a single, double, triple or quadruple outlet set up. The face plate has a raised edge on the inside back of the plate that allows a decora outlet to fit inside it. This will assure that the outlet holes for the electrical device that is being plugged in will align every time and cannot get out of alignment.

Light Switch Plate. This will fit around a standard decora light switch. The back of the plate has several raised edges to align the switch with the plate for proper fit.

Blank Plate. This is designed to be install into the mud ring like the other plates but it has no holes in it. The general purpose of this would be to conceal wire junctions and unwanted devices. Most building codes require that you have access to all wire junctions so this will allow you access but will help hide them if you paint the plate.

Snap in connector or keystone plate. This is used mostly in the low voltage field. They use snap in connectors to set up wall plates in any configuration you would like. These can include but are not limited to Coax Connectors. USB connectors, RJ11, and RJ45 connectors. The connectors are either mounted to a piece of plastic or are molded into a piece of plastic that is designed to snap into a square hole on a wall plate. These plates come in a variety of hole configurations

Mud Plug. A mud plug is a device that is used in the construction process but it is removed and either used on another project or is discarded when the construction is complete. When the original box is nailed to the stud and the drywall is installed and the mud ring is installed you then install the mud plug in the hole in the mud ring. The purpose is to allow the drywall or mud or plaster or whatever device is used to finish the surface can be installed over the mud ring and allow the inside of the mud ring to remain clean and free from debris so the face plate can be seated in the mud ring correctly. Mud plugs come in single, double, triple and quadruple configurations. They have a small groove in the top and bottom f the device so they can lock into the mud ring and not fall out. They also have a small hole in the top and bottom to allow you to insert a screw driver into it and remove them after painting is complete.

Paint plugs are devices that are designed to cover the outlet, RJ1, RJ45, light switches and electrical outlets and protect them from paint and construction debris during the course of normal construction.

Background of the invention

For years we have had wall mounted high and low voltage devices in our homes and businesses. They include the device itself and then so e kind of cover plate that covers the wiring and the junction between the installation box and the drywall or plaster. We have learned to live with the light switches, outlets, TV jacks, Computer jacks, security cameras, motion detectors and many other wall mounted devices. The wall plates for these devices are generally a color that is determined by the manufacturer. There is the basic ivory, gray, black, white etc. This is the way high and low voltage electrical has been done for years.

Most Interior designers and home builders and even many home owners do not want to see these devices but. They must live with looking at them because we either need them or they are part of a building code that requires them.

By eliminating the colored surface mount plate and recessing it in the wall and allowing it to be painted the color of the wall we have drastically changed what people are used to seeing.

Attached Drawings for Single, Double, Triple and Quadruple applications